2007-01-06

|

A little pice of advice, (or WARNING if you like.)

I don't care if this is a laser product or not, or if you go blind or maim yourself in any kind of horrible way. Only a very 'skilled' individual would be 'lucky' enough to injure himself by peeking into the lens with the power on, holding still untill total blindness occures. What I do care about is that the GD-ROM drive is a sensitive pice of equipment. If you crack, scratch, move, drop or bend certain details inside the drve, the drive could stop working properly. |

This page applies to all maintnance and/or repair to Sega's GD-ROM drive.

Cleaning

the GD-ROM drive inside should be made with utmost care and consideration

for the drive's internal parts. It is a simple but delicate construction

which isn't too different from any PC or other electronic home appliances.

But, what is important to remember is that the GD-ROM drive is a very

exclusive device by itself, and regarding spare parts. If you break

it, you must find another drive.

With that said I'll get into the details of how to disassemble, clean,

and reassemble the unit. I hope I don't have to remind you to thoroughly

wash your hands in soap before working. If we wouldn't appreciate hygien

we wouldn't consider cleaning our GD-ROM drive.

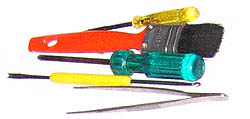

Tools you need:

|

-

A paintbrush (dusting)

- tweezers (positioning details) - small slotted screwdriver (support) - a little hook (pulling / guiding leads) - two sizes of phillips head screwdriver - a steady table with some damping |

|

|

Your

simplest and most basic tool is the screwdriver. They are made

in different shapes and sizes for a reason - never ever challenge

the screw! (You don' eat soup with a fork either, or cut meat

with a spoon, do you?)

|

Things

you should know:

There are several types of screws in the GD-ROM drive, they are to be

kept appart from each other, and used only in their designated place.

The threading is different between each type, putting a wrong type in

a metal threading will damage the threadings of both the screw and the

screw-hole, *and* it will damage the new screw which you will try to

screw into that threading.

I've devided all screws into groups. Refering to an certain screw type

will from now be very easy. Open a new browser window or save the picture

to your hard drive, and have it next to your reading for quick referens.

| Group

1 Holds two metal plates together, introduced in sectiion 'DISASSEMBLING D'. |

Group 2 Holds the 'SCSI connector-pcb' in place, section 'DISASSEMBLING F'. |

Group

3 These screws attach the >fan retainer< to the fan. The smaller flat-head screw holds the ''lock-tap retainer'' in place from within the upper lid, with one group-1 screw. |

|

Group 4 These secure the motor & laser-unit 'nest' to its metal base. 'DISASSEMBLING Q'. |

Group 5 Four fine threaded M3 screws with permanently attached spring washers, are used in metal to metal parts spread over a few sections. |

Group

6 Five if these screws hold the main drive case together, two hold the security de-activating mechanism on the upper plastic caseing, and two mount the fan retainer to the lower plastic casing. |

DISASSEMBLING

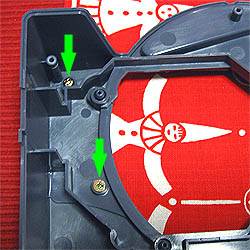

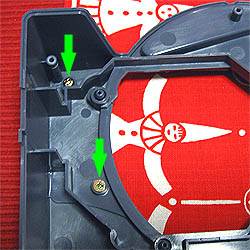

Green arrows mark out general screw positions. Orange arrows call for closer attention or point out areas which need extra caution.

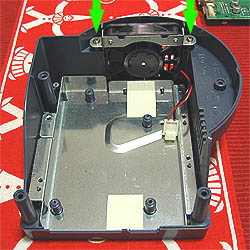

| DISASSEMBLING

A Remove the little M3 phillips (or pozi) screw marked with the green arrow in the picture. You could leave it just as well, but since we are going to remove other details later, we need the lid open. This screw has been omitted in the screw-group overview with purpose. It's a little M3 thread which sometimes is missing in used drives. |

|

|

DISASSEMBLING

B

Turn the drive upside down and remove the five screws (group-6) marked with green arrows. |

|

|

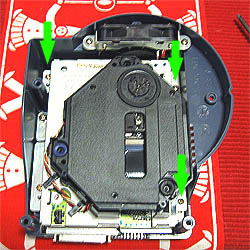

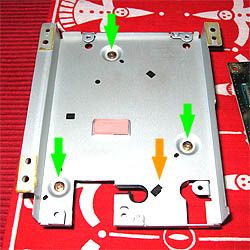

DISASSEMBLING

C

Turn the drive back to upside and remove the three screws marked with green arrows. The upper left screw is a group-6, the other two on the right are group-5 screws. Then try to evenly lift up the motor/laser unit holding it by its sides. Rock gently if you have to. |

|

|

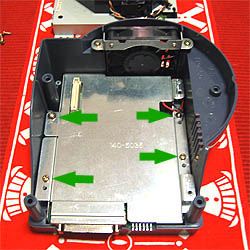

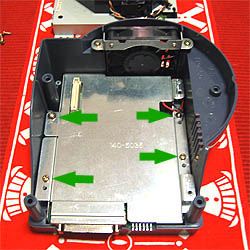

DISASSEMBLING

D

Remove the four screws marked with green arrows. The upper left screw is a group-2 screw. The remaining three are group-6. This metal plate should be quite loose once the screws are gone. |

|

|

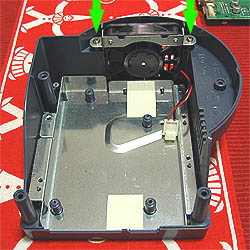

DISASSEMBLING

E

Turn the drive 90 degress counter clockwise and lift up the metal plate revealing the SCSI connector-pcb. But be carefull not to lift it all the way. You must first disconnect the fan from the board. This moment can be quite tricky, so watch what you are doing. Use your nails or a slotted screwdriver to push away the nylon connector. |

|

|

DISASSEMBLING

F

Turn the drive 90 degrees clockwise, back as it was. (Or leave it as you feel most comfortable, I'm just turning it to get a good angle for my camera.) Loosen the three group-2 screws, and the one group-5 screw marked with an orange arrow, loosening the pcb retainer. Remove the pcb. |

|

|

DISASSEMBLING

G

The two screws attaching the fan to the plastic mold are group-6. Remove them. At this point you would want to get closer to your kitchen sink, and have your brush ready. Gently blow away from you, into the sink as you lift the fan out of its place. Leave the fan in the sink while softly blowing air and removing dust sediments from the casing. The fan is cheap type >> look << A square 60 x 10 (mm) |

|

|

DISASSEMBLING

H

After you're done parting the fan from its retainer, put the fan into hot water with a dash of household detergent. Leave it to soak. Now let's focus on the top mold of the drive casing. The security de-activating mechanism is fastened by two group-6 screws. The mech is a two-piece unit which is joined by two more screws locked with 'lock-tite'. Leave them. Wash the mech as it is. (Mind the spring!) |

|

|

DISASSEMBLING

I

Turning the top mold a 180 degrees... ... the upper screw is a group-6, and the bottom screw (also in picture H, not mentioned) is group-3, the small one in that group. Removing these will detach the smaller section of the top casing, I call it the 'lock-tap retainer' as it retains the lid lock-tap. |

|

|

DISASSEMBLING

J

Look how nicely it comes off. You almost don't need this part... Now it's time for a good bath! Throw all plastics into the bubbles and give them a good scrub, ( ! ) with a soft sponge that is. Don't use any kinds of abrasives or polish. Just plain sponge and nylon brush will do the job. Remember not to mix metal parts with plastics as metal can scratch the plastic parts. |

|

|

DISASSEMBLING

K

Notice the fragile switch at the bottom right? Blow away all dust gathered there. If there's plenty, use the brush gently. Also at this point you can clean away dust on the outer surfaces with your brush. Make sure you blow in the proper direction, down the sink preferably. The inside of the laser-unit's 'nest' is seemingly clean as it's kept well isolated from the air flow in the rest of the casing during operating. |

|

|

NOTE!

You will need to bend the two retainers upwards and slide the lead harness outwards. Both of the retainers must let go of the leads for you to be able to lift the motor-laser unit out of its 'nest'. |

|

|

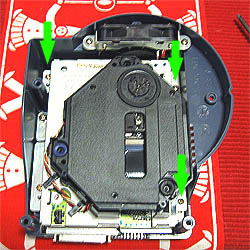

DISASSEMBLING

L

'Laser upside down'! This moment is best performed holding the drive in one hand, minding not touching the lens, and working with the other. You must pay close attention to the laser unit not falling out, it is loose! All screws here are group-1 except the upper left one which is a group-5 screw. This piece of thin metal shield can be tricky to remove even once the screws are out. Force it evenly starting with corners. |

|

|

DISASSEMBLING

M

As you can see it's not impossible to remove the shield. Just pull upwards at the corners. Do not scew or slide sideways, components may get in the way. |

|

|

DISASSEMBLING

O

|

|

After removing

the shield, flippig the assembly back upside again, you will now

remove the laser unit from it's 'nest'. You have already detached

the two cable clamps securing the power harness (Note! section

'K') so all you need to do is carefully guide the flat lead, and

the power harness, out of the 'nest'. |

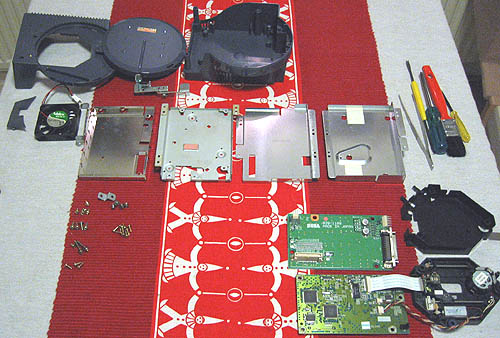

Note: The orientation and position of the modules pictured above is correct except for the laser-unit (rightmost) is on its back due to 'opening' like a clamshell. The pcb goes straight under the metal base, with the laser unit 'closing' from above, ending up in its plastic 'nest'.

|

More

pictures (high resolution)

|

|

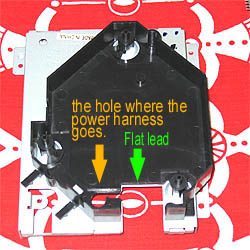

DISASSEMBLING

P

Details explained. To trick the leads to come out of their windings is the biggest challenge. The flat cable is quite easy, it's the power harness that needs guiding and pushing in the desired direction, and over the little tab that prevents the power harness from accidently falling out of its place. |

|

|

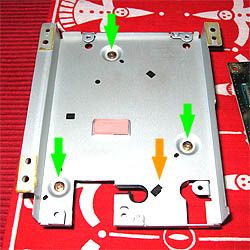

DISASSEMBLING

Q

Flipping the lot once more, all three screws in the picture are group-4. The orange arrow points at the little tab which hooks in place once the plastic 'nest' is aligned correctly. There are several notches which retain the 'nest' steady to the metal base. When reassembling make sure the plastic pins are well placed in all notches. That square little 'pinky' in the middle is best left alone. It's glued to the metal and is a cooling transmitter for an IC located on the drive's 'controller pcb'. |

|

|

DISASSEMBLED

R

|

|

|

Here's

your drive boy. Now put it together! You know how?

|

... well, you'd better. Or get a new drive from Sega.

REASSEMBLING

| REASSEMBLING

A Let's start by making sure all our plastics are nicely dry. I use put them ontop of my vacuum for 15 minutes where the warm exhaust evaporates almost every drop of water. I often help a bit by manually blowing air into screw holes and other hard to reach places. Use a tooth pick to reach deeper and then touch your lips with the pick to check for moist. |

|

| REASSEMBLING

B First plate in place. You should wash your metal parts with a sponge to make them nice and shiny. They dry pretty quickly since they are very simple. Remember to check that all notches are filled / occupied by the plastic pins beneath. Make sure that the plates lay flat and snapped into position. Otherwise you will not be able to close the thing shut at the end. |

|

After a bath and some scrubbing your fan should dry in a half an hour above the vaccum. Give it an occasional blow under its blades to force the water out. Check its rotation resistance, it shoud spin easilly. Otherwise swap it for a new one. Get Papst or whatever.

| REASSEMBLING

C Reassembling is very much the reversed procedure of the disassembling. However, when reassembling the drive we must pay close attention to how the leads are placed, so that there will not be any jammed, which could ultimatly cause a short. We are already familliar with the screws, the retainer is attached to the fan with the two group-3 (long ones), and mounted inside with group-6. Air flow direction should be 'out'. |

|

|

NOTE!

Make sure that the fan leads do not get in the way of the blades, squeezed between the fan and the wall, or cut by metal egdes! Leads should exit at the lower right corner. |

|

|

REASSEMBLING

D

|

|

|

REASSEMBLING

E |

|

|

REASSEMBLING

F |

|

|

REASSEMBLING

G |

|

|

REASSEMBLING

H |

Note that the the assembly in the bottom picture is rotated 180 degrees contra the modules in the middle picture. |

|

NOTE!

Flipping the lot a last time, will leave you with the task of attaching the laser & motor unit's power harness under the clamps marked with green arrows. Simply slide them under as the clamps are snap-in designed for quick assembling. |

|

|

REASSEMBLING

I |

|

|

REASSEMBLING

J |

|

|

REASSEMBLING

K |

|

|

REASSEMBLING

L |

|

|

REASSEMBLING

M |

|

|

REASSEMBLING

N |

|

|

REASSEMBLING

O |

|

And

there you have it! A GD-ROM drive clean as a whistle!